Worm Wheel Manufacturers

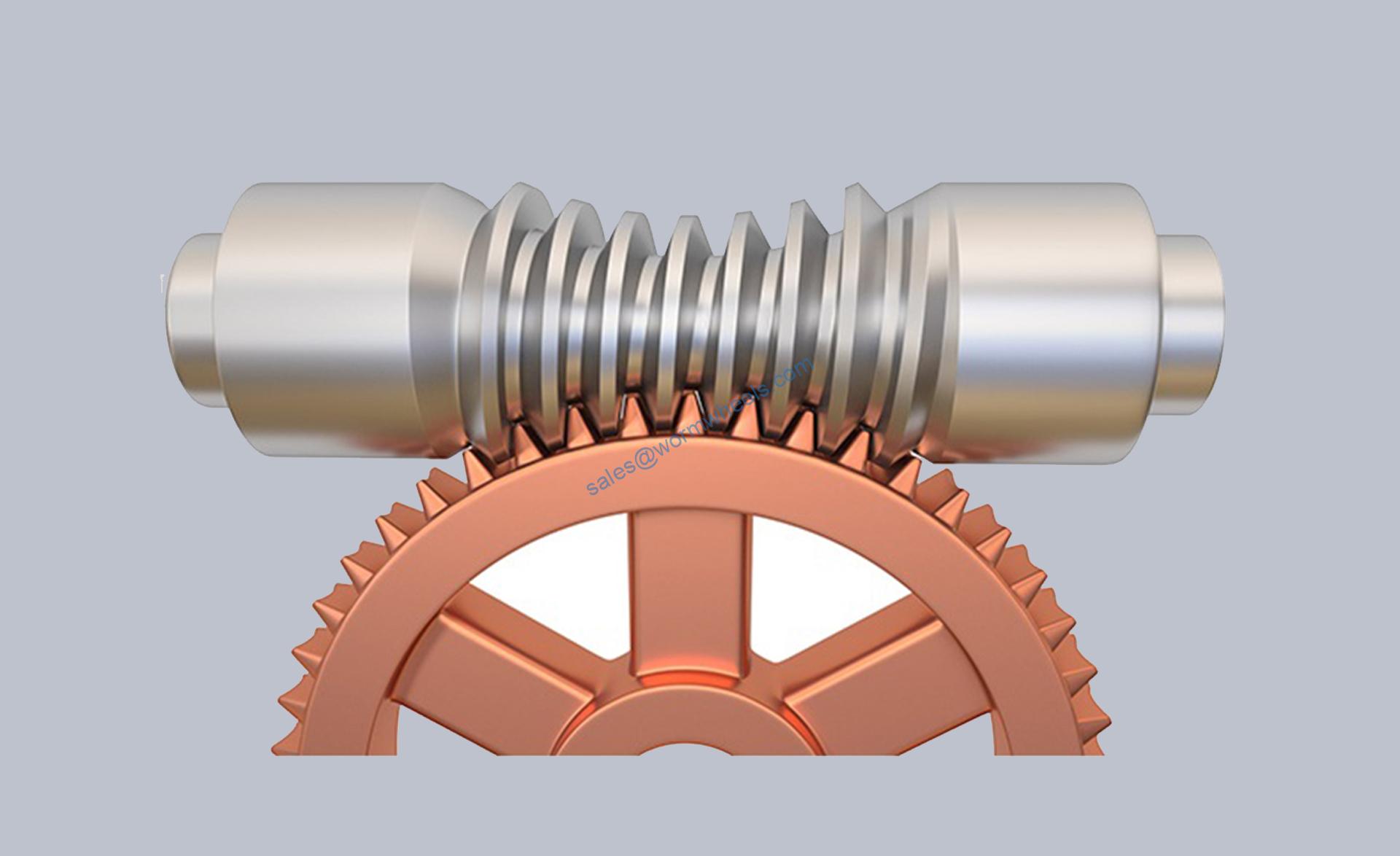

The worm wheel mechanism is often used to transfer the motion and power between two staggered shafts. The worm and wheel gear is equivalent to the gear and rack in its middle plane, and the worm is similar to a screw in shape. The gear reduction ratio of the worm gear is generally 20:1, sometimes even as high as 300:1 or more.

What is a Worm Wheel

If you want to get a larger gear reduction ratio, you need to use worm gear. The gear reduction ratio of worm gear is generally 20:1, sometimes even as high as 300:1 or more.Many worm gears have an interesting feature that other gear sets don’t: the worm can turn the gear easily, but the gear can’t. This is because the protruding angle on the screw is very shallow. When the gear tries to rotate the screw, the friction between the gear and the screw will keep the screw in place.

What is the Gear Ratio of a Worm and Wheel?

Typically, the transmission worm wheel gear ratio is a factor of the pitch diameter and lead angle. In the case of worms, the pitch diameter is uniform and the lead angle increases with the number of threads.

The gear ratio of worm and wheel can be as high as 100. This is possible because of the helical movement of the worm. However, this helical movement is problematic and does not allow power transfer in the correct direction. During sliding, the worm slowly wipes off the lubricant film. This is called sliding wear. Fortunately, worm gears have high relative sliding speeds and low vibration. They are difficult to lubricate and therefore require special lubricants.

Worm and Wheel Examples

If you need customized products, or the products you need are not found on our website or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

-

Duplex worms and worm wheels

-

Factory Custom Precision Worm And Worm Wheel

-

Forging Worm Gear Screw Shaft Coupling And Worms Wheels

-

Mild Steel Worm Shafts

-

Other Products

-

Steel Worm Gear Shaft For Industrial

-

Transmission Worm Gear Worm Shaft For Automobiles & Other Vehicles

-

Wholesale Exporter of Worm Wheel and Gear Shafts

-

worm gear and worm shaft m2.5 worm wheel

-

Worm Gear and worm wheel

What Is a Worm and Wheel Used For?

Worm and wheel can be made from a variety of materials. Typically, bronze is used for worm gears. Aluminum bronze is an alternative material that offers a good balance between machinability and wears resistance. Cast iron is another commonly used material. These are ideal for light loads and are inexpensive.

In its basic form, the worm and wheel are two gears placed inside a protective case. Gears are matched to vary torque and output speed.

Precision worm wheel are used in a variety of other applications, including anti-reverse systems and reversing motors. However, worm gear combinations are not as reliable as other gears. It can also suffer from inefficiencies, which can be reduced with proper lubrication.

Worm Gear and Worm Wheel Calculation

There are two general methods considering the calculation of China worm wheel gears. One is a physically based model, and the other is a semi-analytical model.

The physics-based model considers a simplified cylinder with an interacting surface A. This simplified geometry results in a lower heat transfer coefficient than a real worm shaft. It also creates less turbulence in the oil than in the real thing.

Semi-analytical models provide a more detailed model. It calculates the local heat flux strain and the local Hertzian contact stress from the local coefficient of friction. These parameters are calculated iteratively based on the local contact temperature. It also takes modernization into account.

Worm Wheel Suppliers

As a supplier, we specialize in the production of precision worm gears. We offer single-thread worm gears, double-thread worm gears, and splined-bore worm gears. These gears are used in various applications, such as automotive power steering, machine tools, and speed reducers.

We can provide hundreds of thousands of products to meet different equipment needs. We can provide the best solution for our customers. And the manufactured worm gear has excellent performance and durability and can also provide customers with high precision and low noise.

Application of Worm and Worm Wheel

Worms and worm gears are available for light and heavy-duty applications. These worm and worm wheel applications include rock crushers, conveyors, and elevators. The weight and speed of the load can determine the type of lubricant used.

Unlike most gears, worm and worm gears are self-locking. This feature is especially useful in pendant installations. It prevents reversal of motion and provides braking. However, it is important to use the correct type of lubricant to prevent wear.

Automatic Door System

These systems require movement in one direction, blocking the system at the end of the run. This mechanism can be used to open and close the door because every time the worm makes contact, the door closes.

Musical Instruments

Worms are often found in the tuning systems of guitars, violins, and other stringed instruments. Their enormous mechanical force tensions the strings effortlessly.

Automotive Steering Systems

A steering system of an automobile uses a worm as a basic component. In these systems, the worm is always in mesh with the spur gear. The screws attach to the steering wheel through the “steering column,” and the wheels attach to the steering arms.